Laser solutions for Material Processing

Lasers for metal processing are based on High-power Lasers that generate intense light beams to transform different type of materials in fabrication. This can include laser welding, laser drilling, laser metal cutting, laser engraving or cleaning different materials as plastics, wood and metal.

- Plastic, wood, metal and fabric Marking

- Plastic, wood and metal Engraving

- Metal Welding

- Metal/steel stamping, bending, heat treatment

- Plastic Welding

- Laser Soldering

- Laser Brazing

- Laser Cladding

- Laser Metal Cutting

- Metal Hardening and Softening

- Laser cleaning

- Laser-assisted roll-forming

Technical parameters

| wdt_ID | Application | BPP | Wavelength | Output Power | Rep.rate | Pulse width |

|---|---|---|---|---|---|---|

| 1 | Marking/Engraving | 0.3 – 5 | NIR | 10 – 100 | N/A | N/A |

| 3 | Metal welding | 1 – 40 | NIR (blue for Cu [red-metals]) |

1,000 – 10,000 (thick sheets need more power) |

N/A | N/A |

| 5 | Plastic welding | 30 – 300 (sometimes ~ 10) | Technology shifts from 1 µm to 2 µm | 10 – 200 | N/A | N/A |

| 7 | Soldering/Brazing | 10 – 80 (soldering) 30 – 500 (brazing) |

NIR | 10 – 100 (soldering) 300 – 8,000 (brazing) |

N/A | N/A |

| 9 | Cladding | 30 – 300 | NIR (blue for Cu [red-metals]) |

1,000 – 10,000 | N/A | N/A |

| 11 | Cutting | 2 – 10 | NIR | 10 – 10,000 (high power for metals) |

N/A | N/A |

| 13 | Hardening/Softening | 50 – 1,000 | NIR | 2 – 20,000 | N/A | N/A |

| 15 | Laser Cleaning | N/A | 1,064 nm | 100 – 1,600 | 10 – 20 kHz | < 100 ns |

Product Carousel Tabs

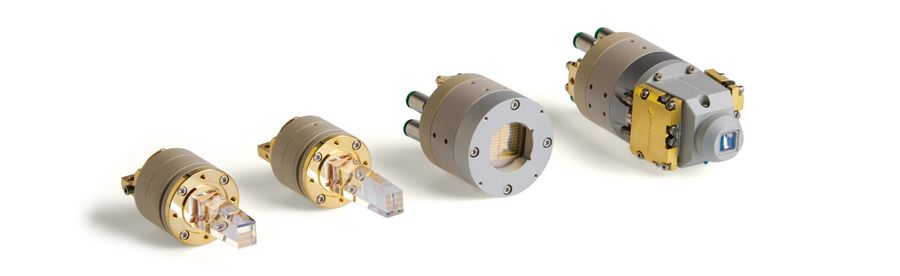

Vertical Diode Lasers

Vertical diode laser assemblies, efficiently cooled with conduction or millimeter water channels cooling circuit. Our vertically structured packages are mounted with a Patented Solder-free Clamping™ technique that allows high cooling efficiency and large operation and storage temperature range. The Innovative Monocrom Clamping™ technology , designed and developed by Monocrom, eliminates the undesired “smile effect” and prolongs laser lifetime.

Choose between different architectures, number of laser bars per stack and tune the central wavelength to your needs. Full range of wavelength offered: 760 nm, 808nm, 880 nm, 915 nm, 940 nm, 976 nm, 1060 nm, 1470 nm, 1550 nm, 1940 nm.

Fiber-coupled Lasers

Fiber-coupled Lasers

Highly efficient fiber coupled diode lasers with Monocrom Solder-free laser bar Clamping™ technology. The lack of a “smile” effect results in an optimum coupling efficiency to the optical fiber. We also provide wavelength stabilized fiber-coupled laser modules with a grating for wavelength locking. Having a low smile results in an exceptionally well-controlled feedback, which increases the locking efficiency and production repeatability.

For the most demanding applications of high brightness (radiance), we offer fiber-coupled high power diode laser systems capable of delivering 1 kW in power in continuous wave (CW) at a single wavelength.

HiEN Pulse 400-YAG

The HiEN Pulse 400-YAG utilizes a proven Nd:YAG crystal, valued for its high thermal conductivity, mechanical strength, and efficient energy extraction. Its isotropic nature eliminates polarization-related distortions, ensuring stable beam quality and simplified alignment. With excellent resistance to thermal stress and long operational durability, Nd:YAG provides a reliable, high-performance platform for demanding laser applications.

This laser delivers 400 mJ at 1064 nm, with frequency-converted outputs at 532 nm and 355 nm, running at 150 Hz with 10 ns pulses. What distinguishes it most is the remarkable pulse energy stability – RMS fluctuations kept around 1% across all wavelengths. By combining efficient thermal handling with a precisely designed MOPA configuration, the system maintains reliable performance with drift limited to ±1%.

Its smooth super-Gaussian beam profile ensures smooth energy distribution, an essential advantage in nonlinear spectroscopy, OPO and Ti:Sapphire pumping, and precision ablation where uniformity matters most.

A patented solder-free clamping technology extends diode lifetimes to over one billion shots, ensuring stable performance while minimizing service interruptions. This unique design also improves thermal management of the pumping diodes, adding another layer of operational security.

With its modular structure, customizable output, and exceptionally low-maintenance operation, the HiEN Pulse 400-YAG stands as the long-lasting, high-energy nanosecond laser of choice for advanced research and industrial applications.

Core Features

• Advanced DPSS pumping technology

• Uniform beam profile at high repetition rate

• Outstanding pulse energy stability

• Versatile, modular platform design

• Customizable output parameters

• Extended diode lifetime with patented solder-free clamping technology

• High-efficiency DPSS pumping heads

Applications

• Nonlinear spectroscopy

• Plasma research

• Precision material ablation

• Laser ultrasound imaging

• Pumping of OPO, Ti:Sapphire, or dye lasers

• Remote sensing

• LIDT (laser-induced damage threshold) optics testing

HiEN Puls 300-YLF

The HiEN Pulse 300-YLF is built utilizing PH6000 pumping module based on Nd:YLF crystal featuring inherently low thermal lensing. This ensures better beam quality, purer polarization, and reduced mechanical stress, making it an excellent choice for high-energy operation regime.

The laser delivers up to 300 mJ at 1053 nm with harmonics at 526.5 nm and 351 nm, operating at 100 Hz with 10 ns pulses. Beyond these numbers, what truly sets it apart is its exceptional pulse energy stability – RMS values in a range of 1 % across all outputs. Thanks to reduced thermal load and a carefully engineered MOPA architecture, performance remains consistent with long-term drift under ±1 %.

The smooth super-Gaussian beam profile provides uniform energy distribution, which directly enhances outcomes in non-linear spectroscopy, OPO, Ti:Sapphire, or dye laser pumping, and material ablation where precision and homogeneity are critical.

A patented solder-free clamping technology extends diode lifetimes to over one billion shots, ensuring stable performance while minimizing service interruptions. This unique design also improves thermal management of the pumping diodes, adding another layer of operational security.

With its modular structure, customizable output, and exceptionally low-maintenance operation, the HiEN Pulse 300-YLF stands as the long-lasting, high-energy nanosecond laser of choice for advanced research and industrial applications.

Core Features

• Advanced DPSS pumping technology

• Minimal thermal lens influence

• Outstanding pulse energy stability

• Versatile, modular platform design

• Customizable output parameters

• Extended diode lifetime with patented solder-free clamping technology

• High-efficiency DPSS pumping heads

Applications

• Nonlinear spectroscopy

• Plasma research

• Precision material ablation

• Laser ultrasound imaging

• Pumping of OPO, Ti:Sapphire, or dye lasers

• Remote sensing

• LIDT (laser-induced damage threshold) optics testing

HeatMe

Edge-emitting Solution for Industrial Heating

Direct diode solution allowing you controlling your Industrial heating application more accurately.

Controlling each and every part of the HeatMe module independently enabling much more flexibility with the targeted material.

This cost-effective solution is the next evolution in Heat treatment applications providing a scalable, flexible state of the art Heat source, which can be optimize to the necessity of your application.