Sorting in Food Production

Laser Technologies for Sorting in Food Production

Laser technology for sorting enables efficient quality control of optimized industrial processes. Its use in the food and beverage industry is widely spread in classifying fruits, vegetables and nuts on the basis of structural or color defects.

Monocrom laser sources come with various optics options and patterns projection to ensure the optimal performace and high accuracy. Applications include in-line detection or monitoring of target parameters such as dimensions, color, size at high speeds, where the targets are moving fast with a wide range of colors and levels of background ambient light. Wavelengths from 375 nm to 1550 nm in a range of power between 1 mW and some watts.

- Sorting in free fall

- Quality control

- Classification

This application list is not intended to be an exhaustive view of laser sources for sensing in production automation. The apllications are by no means limited to these examples, and may serve as a suggestion for similar or completely different applications.

Technical Specifications

Parameters

| wdt_ID | Parameters | A |

|---|---|---|

| 5 | Wavelength | 375 – 2900nm |

| 6 | Power | up to 300 mW |

| 7 | Operation mode | CW modulated up to 20 kHz |

| 8 | Power stability | < 0.5% with temperature variation |

| 9 | Optics | fixed collimated or focusable from 20 mm distance onwards |

| 10 | Boresight | down to 0.2 mrad |

· Very low line bowing submillimeter

· Thermo-electrical wavelength stabilization on request

Product Carousel Tabs

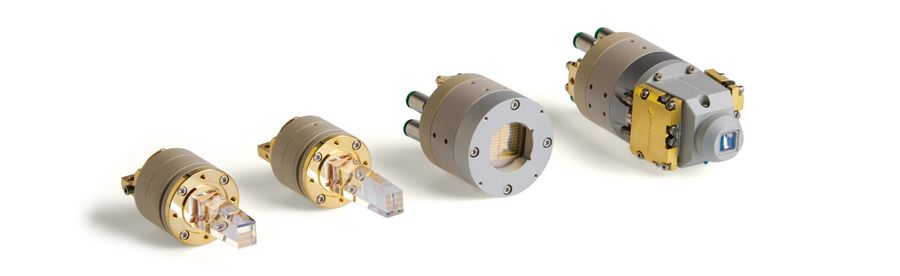

Single Emitters

Single Emitters: Laser diode modules based on single emitters.

Wavelengths between 375 nm – 1550 nm are available in a range of power that starts below 1mW and scales up to some watts.

We can add optics, mechanics and electronics to fit customer’s demands.